Replacing the gearbox in a washing machine requires some basic skills and familiarity with the appliance.

In this article, you will learn what is a gearbox in a washing machine and how to care.

You will also learn step-by-step instructions on how to replace them along with the required tools.

Here’s what this article covers.

- What is a Gearbox in a washing machine?

- Where is the gearbox located in your washer?

- How does the gearbox wear out?

- What happens if the washer’s gearbox gets damaged?

- How to replace the gearbox in a washing machine?

- How to maintain a washer’s gearbox?

- Final Thoughts

- Frequently Asked Questions

What is a Gearbox in a washing machine?

The gearbox is a housing that contains gears and bearings.

It transfers power from the motor to the agitator and spin basket.

The gearbox is filled with oil to lubricate the gears and bearings.

Where is the gearbox located in your washer?

The gearbox is usually located below the wash tub and contains a set of gears that rotate the washer tub.

The washing machine’s gearbox is attached to the main motor.

How does the gearbox wear out?

Over time, the set of gears can become stripped or damaged, causing the washer to become noisy or vibrate.

The common reasons that cause the gearbox to wear out are Oil leaks, Overloading, Insufficient Lubricants, Aging, Improper Maintenance, etc.

What happens if the washer’s gearbox gets damaged?

If the washing machine gearbox gets damaged, it may not be able to properly agitate or spin the clothes.

This can lead to longer wash times or clothes that are not as clean as they should be.

In some cases, the damage may be so severe that the washing machine may need to be replaced.

How to replace the gearbox in a washing machine?

The gearbox in a washing machine is responsible for transferring power from the motor to the various moving parts of the machine.

Typically the gears in the gearbox can wear down due to prolonged usage.

It causes the washing machine to operate in an inefficient manner.

If your washing machine is starting to make noise or is having difficulty in spinning, it may be time to Investigate and replace the gearbox if it’s damaged.

Washing machines usually have a detachable gearbox.

You will need the following tools in order to replace the gearbox safely.

- A screwdriver

- A wrench

- A new gearbox

- Some grease (optional)

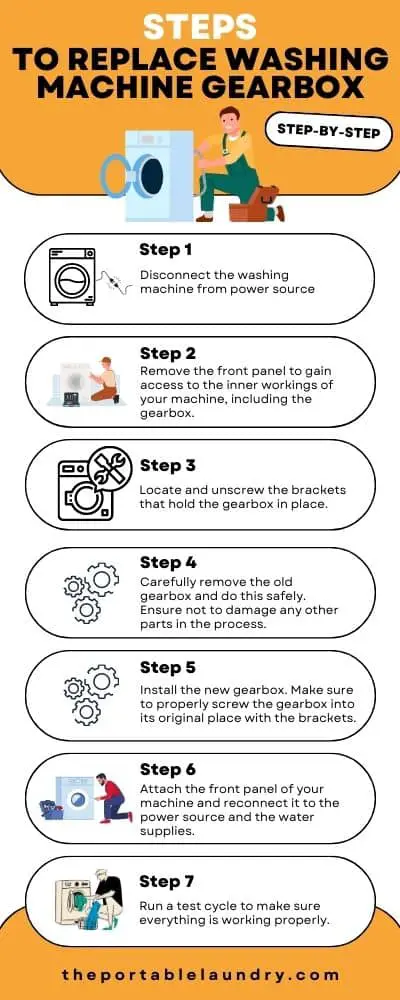

Once you have everything ready, simply follow the step-by-step guide below to replace the washer’s gearbox.

Step 1: Disconnect your washing machine from the power source and the water supplies.

Step 2: Remove the front panel of your machine. This will give you access to the inner workings of your machine, including the gearbox.

Step 3: Locate and unscrew the brackets that hold the gearbox in place. Depending on the model of your washing machine, there may be just one screw or multiple screws.

Step 4: Once the screws are removed, carefully remove the old gearbox. Do this safely and ensure not to damage any other parts in the process.

Step 5: Take a look at the new gearbox to familiarize yourself with its parts and how it goes together. Now, Install the new gearbox. Make sure to properly screw the gearbox into its original place with the brackets.

Step 6: Now, attach the front panel of your machine and reconnect it to the power source and the water supplies.

Step 7: Do not forget to run a test cycle to make sure everything is working properly.

Note: Make sure all the screws are tight and apply some grease to the moving parts if needed.

How to maintain a washer’s gearbox?

If your washing machine has a gearbox, it’s important to keep it well-maintained.

Otherwise, you may end up with a broken washing machine.

Here are some caring tips on the washing machine gearbox.

Keep the gearbox clean

This means cleaning out any dirt, debris, or soap buildup that could impede the gears from working properly.

Lubricate the gearbox

This will help to keep the gears functioning smoothly.

You can use a variety of lubricants, but make sure to use one that is compatible with your washing machine.

Check the gearbox regularly for wear and tear

Inspect the alignment of the gears regularly and adjust them if necessary. If there are any damaged or worn gears, they should be replaced instantly.

Avoid Stressing the Gearbox

Avoid putting stress on the gearbox by using only the recommended wash program settings and avoid overloading the washing machine.

By following these simple tips, you can help ensure that your washer’s gearbox will last longer.

Potential problems that you may encounter during the replacement process

During the washing machine’s gearbox replacement process, you may encounter several potential problems.

Here are some common issues that you may encounter along with their troubleshooting solutions which you can try before approaching a professional.

Difficulties in Removing Old Gearbox

If the old gearbox is stuck or difficult to remove, avoid using excessive force that may damage other components.

Instead, try applying penetrating oil to loosen any rust or debris around the screws.

Gently tap the gearbox with a rubber mallet to free it. If the problem persists, consult a professional technician.

Misalignment of Gears

Improper alignment of gears can lead to noise and inefficiency.

Make sure to align the new gearbox correctly with the washing machine’s motor and agitator.

Double-check the positioning and tighten the brackets securely.

Leaks or Oil Spills

If you notice oil leaks or spills during the replacement process, stop immediately and address the issue.

Ensure that the gearbox is properly sealed and that the gaskets or O-rings are in good condition.

Clean any spilled oil thoroughly to prevent accidents.

Inadequate Agitation or Spinning

After replacing the gearbox, if the washing machine still doesn’t agitate or spin correctly, recheck the installation and connections.

Ensure that all wires and components are correctly attached.

If the problem persists, it could be an electrical or motor-related issue, and professional assistance may be required.

Excessive Noise or Vibrations

Unusual noises or vibrations after the replacement could indicate a problem with the gears or motor.

Check for loose screws or any misalignment in the gearbox.

Lubricate the gears properly and ensure that they are not damaged.

If the issue continues, consult a qualified technician.

Electrical Malfunctions

If your washing machine experiences electrical malfunctions, such as sudden shutdowns or erratic behavior, disconnect it from the power source immediately.

Check the wiring and connections for any damage or loose ends.

If you are uncertain about electrical troubleshooting, seek professional help.

Gearbox Compatibility

Ensure that the new gearbox is compatible with your specific washing machine model.

Check the part number and specifications before making the purchase.

Using an incompatible gearbox can lead to further problems and may void your warranty.

Remember, safety is paramount when working with electrical appliances.

Always disconnect the washing machine from the power source and water supplies before attempting any repairs.

Reach out to a professional

If you encounter complex issues or lack confidence in your skills, it is best to seek the assistance of a qualified appliance technician.

Final Thoughts

Replacing the gearbox in a washing machine is not a difficult task, but it does require some basic mechanical knowledge and tools.

If you are not comfortable performing this repair, we recommend that you call a qualified technician to do it for you.

However, with the usage of proper tools and instructions, you should be able to complete this repair on your own without any hassles.

Use the washer with recommended guidelines, to prolong the lifespan.

Frequently Asked Questions

Here are some common questions related to washing machine gears that are frequently asked.

Does the washing machine use gears?

Yes, most washing machines use gears to operate. It consists of a series of gears that spin at different speeds. Washers include a gearbox that holds these gears and supportive bearings.

What is the cost of a washing machine’s gearbox?

A washing machine’s gearbox can vary depending on the make and model of the machine, as well as the specific gearbox itself. With that said, In general, gearboxes for washing machines typically cost anywhere between $50 and $200.

How often do I replace my washer’s gearbox?

Gearboxes in washing machines can last up to 10 years or even more. If your washer is creating problems you will first need to find out if the gearbox is the culprit or not. Accordingly, you may lubricate, clean, or fix them. If that doesn’t work, simply replace the gearbox of your washer.

You May Also Like

- How to Install Waste Pipe for Washing Machine? (Step-by-Step)

- How to Install a Washing Machine Drain Pan?

- How to Install a Clothesline Tightener? (Step-by-Step)

- How to Vent a Washing Machine Drain Pipe? (Step-by-Step)

- How To Loosen Washing Machine Hose Safely? (Easy Guide)

- How to Reset a Washing Machine? (Step by Step)

- How to fix the 4c error in the Samsung washing machine?

- How to Unlock A Washing Machine Door Mid Cycle?

- How to stop a washing machine mid-cycle?

- How to Clean a Portable Washing Machine?

- How to Troubleshoot a Portable Washing Machine?

- How to Use a Portable Washing Machine Effectively?