The ‘Washing Machine Clutch’ is one of the essential components in a washer that smoothens the wash cycles.

It is a device that helps to engage or disengage the spinning of the inner drum of a washing machine with the agitator.

In this article, we will take a look at what a clutch does and how to tell if it needs to be replaced.

Here’s what this article covers in detail.

- What is a washing machine clutch?

- How does the washing machine’s clutch appear?

- What are the different types of clutches?

- Why is a clutch an important part of the washer?

- When do you need to replace the clutch?

- How to replace the washer’s clutch?

- How to maintain a washing machine’s clutch?

- Final Thoughts

- Frequently Asked Questions

What is a washing machine clutch?

Washing Machine Clutch is also known as a transmission clutch.

A transmission clutch is a device that connects and disconnects two rotating shafts.

In a washing machine, the clutch is what connects the washing machine’s motor to the agitator.

It is usually made up of two parts, an outer ring, and an inner ring. The outer ring is connected to the engine while the inner ring is connected to the agitator.

It’s located between the agitator and the transmission, and it’s an essential part of the machine’s operation.

When the motor turns on, the clutch engages and turns the agitator.

Likewise, when the motor turns off, the clutch disengages and the agitator stops.

How does the washing machine’s clutch appear?

There are different types and models of washing machines in the market, each with its own unique design.

However, most washing machine clutches are located near the bottom of the machine, usually near the agitator.

They typically consist of a small, disk-shaped piece that fits over the agitator shaft.

You can refer to the below image that displays a transmission clutch. This type of clutch is suitable for direct drive washing machines.

What are the different types of clutches?

There are three different types of clutches in a washing machine.

They are the direct drive clutch, the belt drive clutch, and the hydrostatic clutch.

The direct drive clutch

It is the most common type of clutch in modern washing machines.

It is a metal plate that is sandwiched between two rubber discs.

The plate is connected to the motor shaft and the discs are connected to the tub.

When the motor turns, the plate spins and the discs start to rotate.

The direct drive clutch is simple and reliable, but it can be noisy.

The belt drive clutch

It is less common than the direct drive clutch.

It uses a belt to connect the motor to the tub.

The advantage of this type of clutch is that it reduces noise.

The disadvantage is that it can be more difficult to repair.

Hydrostatic clutch

It is the least common type of clutch in a washing machine.

It uses hydraulic fluid to connect the motor to the tub.

The benefit of this type of clutch is that it is very quiet.

The drawback is the expensive repair costs.

Note: Another type includes an indirect drive clutch. These are more common in older machines that help to engage and disengage the washing machine’s motor from the drive shaft. This helps to protect the motor from damage when the washing machine is not in use.

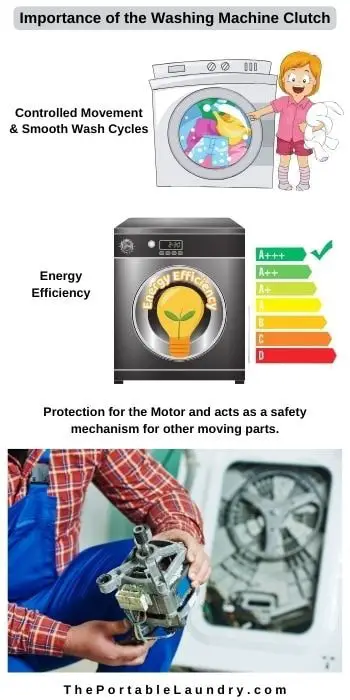

Why is a clutch an important part of the washer?

The clutch is an important part of the washing machine because it helps to ensure that the agitator is only turned on when it’s supposed to be.

If the clutch is not working properly, it can cause the agitator to turn on at the wrong time or to not turn on at all. This can lead to problems with your clothes getting clean.

If you think there might be a problem with your washing machine’s clutch, it’s a good idea to have a qualified technician take a look at it.

They’ll be able to diagnose the core cause of the issue and get them fixed accordingly.

Here are some common reasons why a washing machine clutch is an important component.

Controlled Movement

The clutch enables controlled movement of the agitator, ensuring the clothes inside the drum are agitated and cleaned evenly during the wash cycle.

It prevents abrupt or uneven agitation, which could damage delicate fabrics or reduce washing efficiency.

Protection for the Motor

By disengaging the agitator when not in use, the clutch protects the motor from unnecessary wear and strain, extending its lifespan.

Energy Efficiency

With the clutch’s ability to start and stop the agitator efficiently, the washing machine consumes only the required energy for agitation, making the appliance more energy-efficient.

Smooth Wash Cycles

The clutch’s engagement and disengagement contribute to smooth wash cycles, reducing noise and vibrations during operation.

Safety Mechanism

The clutch acts as a safety mechanism by preventing the agitator from moving when the lid is open or during certain stages of the washing process.

Other Essential Components in Conjunction with the Clutch

Agitator

The agitator is a paddle-like mechanism inside the washing machine drum that rotates and moves the clothes around to facilitate the cleaning process.

The clutch’s engagement with the agitator is crucial for the agitator’s movement during the wash cycle.

Transmission

The transmission is responsible for transferring power from the motor to various components of the washing machine, including the agitator.

The clutch plays a role, in the transmission system facilitating the controlled transfer of power to the agitator.

Motor

The motor serves as the core of the washing machine supplying the energy for its operation.

The clutch establishes a connection, between the motor and the agitator allowing for utilization of the motors power during wash cycles.

Control System

The washing machine’s control system, which includes timers and switches, governs the activation and deactivation of the motor and the clutch.

This coordination ensures that the clutch engages and disengages at the appropriate times during the wash cycle.

Note: These are not the only components that interact with the clutch, the design, model, and features offered by the washer will also determine which components interact wit with the clutch.

When do you need to replace the clutch?

If your washer starts making strange noises, or if it isn’t agitating or spinning properly, then it might be time to replace the clutch.

A broken or damaged clutch can cause numerous problems with your washing machine, so it’s best to replace them at the right time.

You can usually find replacement clutches at your local hardware store or online.

Make sure to carry the existing clutch to get an accurate replacement.

You may simply use the model or the serial number of your washer to identify the exact match.

How to replace the washer’s clutch?

Follow the easy steps below to replace a worn-out OR damaged clutch from your washing machine.

You’ll need some basic tools, including a socket wrench set and a screwdriver.

Step 1: First, unplug your washing machine from the power outlet and shut off the water supply. You may disconnect the hoses if it requires you to move your washer.

Step 2: Next, remove the access panel located at the rear side of the washer. This will give you access to the motor and other parts such as the clutch.

Note: You may have to detach the agitator, motor, and drive belts in the process. Hence securely do your job without damaging any other components of the washer.

Step 3: Locate the clutch assembly and disconnect it from the motor shaft. You’ll likely need to use a socket wrench to loosen the nut that secures the clutch to the shaft.

Step 4: Once the clutch is disconnected, you can remove it from the washing machine.

Step 5: To install the new clutch, simply reverse the steps above. Be sure to tighten all retaining nuts securely before plugging in your washing machine and turning on the water supply.

Step 6: Now, run a test cycle to confirm if everything is working as expected.

If you have reached step 6 it means that you have successfully replaced the clutch assembly.

Common Washing Machine Clutch Issues and Troubleshooting Tips

Washing machine clutches, like any other mechanical component, can develop problems over time.

Identifying and resolving these issues promptly can help maintain the appliance’s performance and prevent further damage.

However, when diagnosing and repairing the clutch, it’s essential to follow safety precautions to avoid accidents and injuries.

Common Clutch Issues

1. No Agitation or Spin

- Issue: The clutch may not engage properly, resulting in no agitation or spinning of the agitator during the wash cycle.

- Troubleshooting: Check for any broken or worn friction pads in the clutch assembly. If the friction pads are damaged, they need replacement.

2. Loud Noise During Operation

- Issue: Excessive noise, such as grinding or squealing, during the wash cycle can indicate a problem with the clutch.

- Troubleshooting: Inspect the clutch assembly for any signs of wear, such as metal shavings or excessive friction. Replace the clutch if necessary.

3. Clutch Slipping

- Issue: The clutch might slip, leading to incomplete agitation or spinning of the agitator, resulting in poor washing performance.

- Troubleshooting: Check for any loose or damaged parts in the clutch assembly. Tighten or replace these components as required.

4. Burning Smell

- Issue: A burning smell during the wash cycle can indicate excessive friction or overheating in the clutch.

- Troubleshooting: Disassemble the clutch and check for any worn or damaged parts. Lubricate the clutch components appropriately to reduce friction.

How to Identify and Resolve Clutch Issues?

1. Visual Inspection

Carefully unplug the washing machine and open the access panel to inspect the clutch assembly visually.

Look for signs of wear, damage, or loose components in the clutch assembly.

2. Operational Test

With the washing machine unplugged, manually rotate the agitator to see if it moves smoothly and engages with the clutch.

Listen for any abnormal noises during this test.

3. Check for Friction Pad Wear

Disassemble the clutch carefully to access the friction pads.

Inspect the pads for wear, thinning, or damage. If needed, replace the friction pads with new ones.

4. Inspect Belts and Pulleys (for belt-drive clutches)

For belt-drive clutches, inspect the belts and pulleys for signs of wear or damage.

Replace worn-out belts or damaged pulleys to ensure proper clutch operation.

Safety Precautions when Diagnosing and Repairing the Clutch

Power Off

- Always disconnect the washing machine from the power outlet before attempting any diagnosis or repair.

- Unplug the machine to prevent electric shocks or accidents.

Follow Manufacturer’s Guidelines

- Refer to the washing machine’s user manual for specific safety instructions and guidelines for diagnosing and repairing the clutch.

- Adhere to all safety recommendations provided by the manufacturer.

Protective Gear

- Wear appropriate safety gear, such as gloves and safety goggles, when working on the washing machine to avoid injuries.

Work in a Well-Ventilated Area

- If using any lubricants or chemicals during repair, ensure proper ventilation in the workspace to avoid inhalation of fumes.

Proper Tool Usage

- Use the correct tools for disassembling and reassembling the washing machine clutch.

- Avoid using excessive force, which could damage components.

Call a Professional if Unsure

- If you’re unsure about diagnosing or repairing the clutch, it’s best to seek assistance from a qualified technician or appliance repair professional.

Final Thoughts

The clutch is a crucial component as it engages the agitator so that it can start moving. Furthermore, it is also responsible to disengage the agitator.

When the clutch goes bad, it can cause all sorts of problems with the washer and requires immediate attention.

Just see if your washer is making any unusual noises, OR vibrating unusually. If that’s the case, it’s likely that the drum, motor, bearing, drive belt OR clutch has gone bad.

You may fix the washer’s clutch at home, but for anything that you are unsure about, contact a professional.

Frequently Asked Questions

Some common questions about washing machine clutches that may be helpful.

How much does it cost to replace the washer’s clutch?

If your washing machine’s clutch has worn out or has gone bad, it may be time to replace them. On average, a washing machine clutch will cost you anywhere between $100 to $200. The cost may vary depending on the washer type and the model.

Where is the washing machine’s clutch located?

The washing machine’s clutch is located on the back of the washer and is attached with screws. It connects the drive shaft to the transmission. You may refer to the user manual of your washer model type to locate the clutches.

You May Also Like

- What is a Water Booster Pump in Washing Machine? (Explained)

- What is a Washing Machine Standpipe? (Explained)

- What is Extra Rinse in Washing Machine?

- What is a Smart Washer and Dryer? (Explained)

- What is IE Error in LG Washing Machine? (And Solutions)

- What Is Rinse And Spin In LG Washing Machine?

- What is Limescale in the washing machine?

- What is an Agitator in Washing Machine?

- What is a Lint Filter in Washer? (10 Things you must know)

- What is Soil Level in Washing Machine?

- What Is RPM in Washing Machine? (13 Things to know)

- What is the Allergiene cycle in an LG washer? (Explained)

- What is Diamond Drum technology in Washing Machine?

- What is NFC in a washing machine? (Explained)